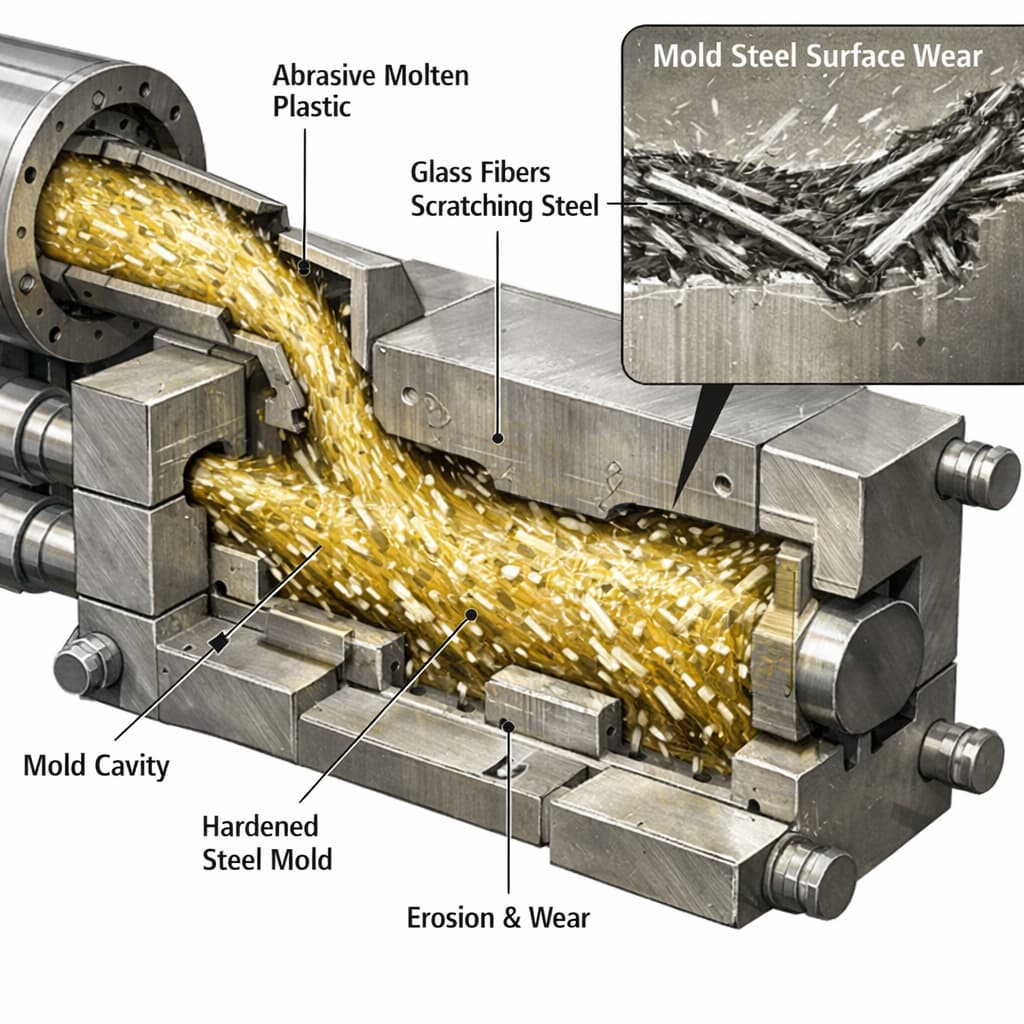

Processing data indicate that, under identical tooling and processing conditions, PA66 GF40 exhibits a mold wear rate 1.6–1.8 times higher than GF30, particularly in high-flow regions. Additionally, high glass fiber systems demand higher injection pressure and speed, further intensifying abrasive effects.

Beyond mechanical abrasion, excessive reinforcement also accelerates thermal fatigue of molds. Reduced thermal uniformity causes larger temperature gradients per molding cycle, increasing micro-crack initiation risks, especially in standard H13 or P20 tool steels.

Industrial experience shows that many failures originate not from insufficient material strength, but from over-reliance on high glass fiber content. In one connector application, increasing fiber content from GF35 to GF50 reduced mold life from an expected 800,000 cycles to less than 300,000 cycles, increasing hidden manufacturing costs by over 20%.

Ultimately, glass fiber content selection is a balance between structural performance, processing stability, and manufacturing economics rather than a pursuit of maximum reinforcement.