В производстве бытовой техники электроизоляция и термостойкость всегда были ключевыми факторами при выборе материала. По мере того, как бытовая техника становится всё более энергоёмкой, компактной и функционально оснащённой, традиционный полиамид 6 (PA6) или Смолы ПА66 Нейлоны с высоким сравнительным индексом трекингостойкости (CTI) больше не отвечают требованиям к изоляции и тепловым характеристикам при длительной эксплуатации под высоким напряжением. Поэтому основным трендом стали модифицированные нейлоны с высоким индексом трекингостойкости (CTI). Нейлоновые материалы с высоким сравнительным индексом трекингостойкости (CTI) снижают риск трекингостойкости и пробоя диэлектрика, сохраняя изоляционные свойства даже во влажных, жарких и загрязненных условиях.

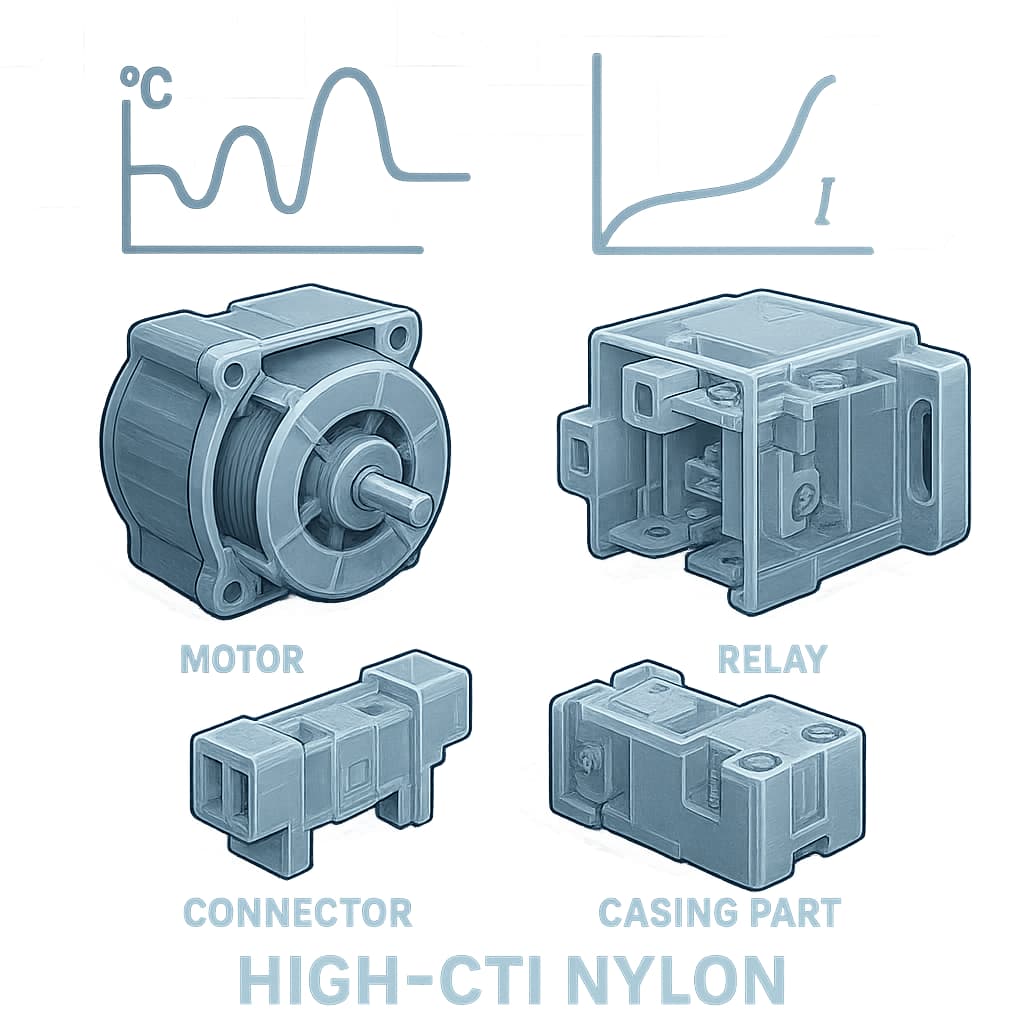

Более высокое значение CTI указывает на лучшую устойчивость к электрическому трекингу. Такие компоненты, как корпуса двигателей, цоколи реле, разъёмы и переключатели, подвергаются длительному электрическому напряжению и локальному нагреву, что приводит к потенциальному поверхностному трекингу при наличии влаги или загрязнений. Стандартный PA66 имеет CTI ниже 400 В, в то время как модифицированные марки могут достигать 600 В и выше, обеспечивая более высокий запас прочности для высоковольтных применений. Повышение CTI достигается за счёт использования антитрекинговых наполнителей, безгалогеновых антипиренов и технологии контроля дисперсии, которые в совокупности снижают поверхностную проводимость и миграцию ионов.

Тепловое сопротивление является еще одним ключевым фактором для компонентов бытовой техники, работающих вблизи источников тепла, таких как кофемашины, фритюрницы или кронштейны статоров электроинструментов. Стандартные нейлоны имеют тенденцию к потере прочности и хрупкости после длительного термического старения. Для решения этой проблемы в полимерную цепь интегрируют ароматические структуры, термостабилизаторы и армирующие системы. Распространенные системы модификации включают смеси ПА66/ППА, сополимеры ПА6Т и нейлоновые матрицы с высокой степенью кристалличности. Эти материалы могут достигать температуры изгиба под действием тепла (HDT) выше 240 °C и температуры стеклования (Tg) выше 120 °C, сохраняя при этом хорошие механические свойства и текучесть.

С точки зрения огнестойкости, Нейлоны с высоким индексом текучести (CTI) обычно соответствуют классу огнестойкости UL94 V-0 без использования галогенных систем. Современные составы используют фосфорсодержащие или азот-фосфорные синергетические антипирены, образующие устойчивый обугленный слой, который блокирует распространение пламени и подавляет дымообразование. Это обеспечивает соответствие стандартам IEC 60335 и RoHS, сохраняя при этом внешний вид и эксплуатационные характеристики.

С точки зрения переработки, термостойкие нейлоны с высоким индексом текучести (CTI) требуют сбалансированной реологии. Их наполненные системы повышают вязкость расплава, поэтому необходимы оптимизированные условия формования: температура формы 90–110 °C, длительная выдержка под давлением и вакуумная вентиляция для предотвращения образования газовых задержек. Для тонкостенных деталей смеси ПА66/ПА6 или составы с улучшенной текучестью обеспечивают сохранение изоляции и улучшенную обрабатываемость. Содержание стекловолокна 30–35% обычно является оптимальным для обеспечения размерной стабильности без ущерба для качества поверхности.

В будущем особое внимание будет уделяться устойчивому развитию и более продуманному дизайну материалов. Био-нейлоны, такие как PA610 и PA1010, в сочетании с безгалогеновыми системами с высоким индексом текучести (CTI) представляют собой экологичную альтернативу. Поскольку бытовая техника продолжает развиваться в сторону более высокой плотности энергии, материалы должны обеспечивать улучшенную изоляцию, более высокую стойкость к тепловому старению и стабильные диэлектрические свойства, что обуславливает использование нейлонов с высокой температурой стеклования (Tg) и сополимеров PPA. Конечная цель — достижение решения, сочетающего в себе «высокую безопасность, высокую термостойкость и низкое воздействие на окружающую среду».